Official Distributor of Matpro Solutions for Kalimantan Island, Indonesia

We are a trusted distributor of Matpro Solutions, a specialized and leading supplier of bulk material solutions, industrial automation, field instruments, and various industrial weighing systems.

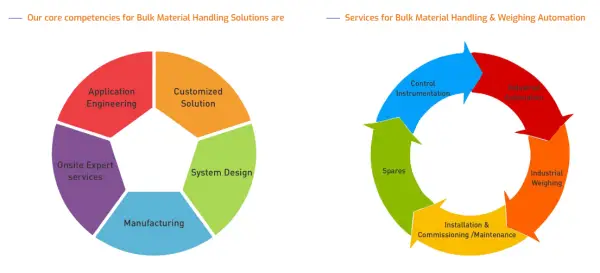

Our expertise covers system design, application engineering, manufacturing, on-site expert services, spare parts supply, and documentation. With a strong foundation in development, stability, innovation, consistency, reliability, and customer satisfaction, we are committed to providing the best solutions for your industrial needs.

- MATPRO Solutions are specialize and leading supplier of for Bulk

material handling and weighing Automation solution - We Started by March 2017

- We are Three Promoters with individuals 25-30 years experience

in the same field - Our fundamentals are development, Stability, Innovation,

consistency, reliability and customer satisfaction - We listen to our customer’s needs, as their process / business

developmental requirements and we design & deliver customized

solution to address their existing challenges and further

improvements - We serve wide range of industrial sector like Food, Pharma,

Chemicals, Steel, Power, Cement, Port, Fertilizers etc

Our Services:

- Maintenance

- Trouble shooting

- Calibration

- Installation & commissioning

- Supply of equivalent and compatible spare parts

for all kinds of existing of and any make of weighing systems.

Our product range

- Conveyor Belt Weigh Scales

- Loadcell- Dynamic application

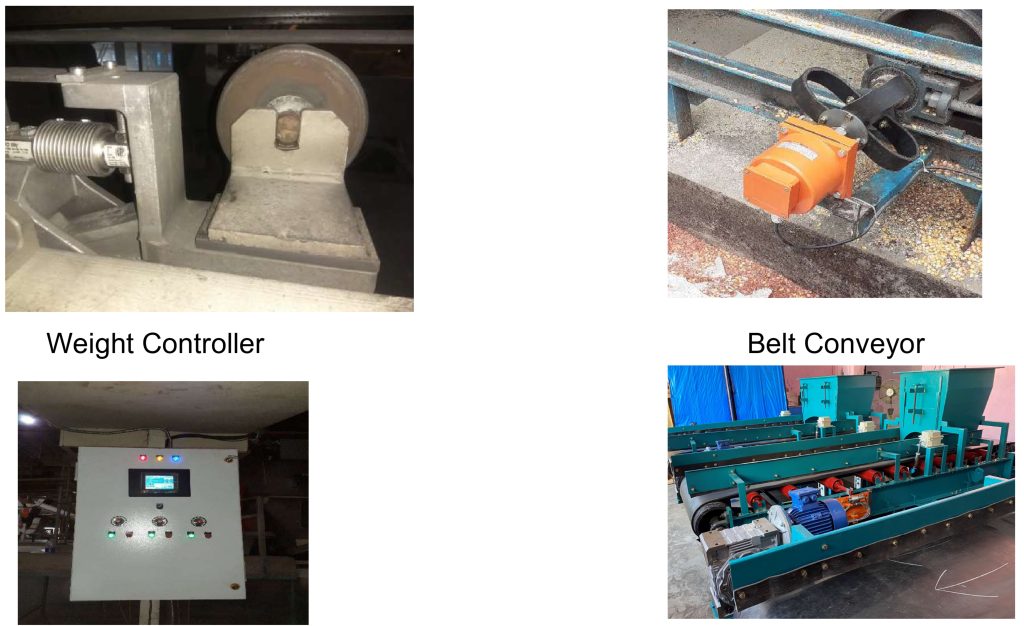

- Weight Controller – MATPRO 7003

- Tacho – Speed Sensor

- Belt Scale

- Gravimetric Belt Weigh Feeder

- Coal Feeder

- Bunker

- Two Stage Coal Sampling system

- Bull Material Handling equipment

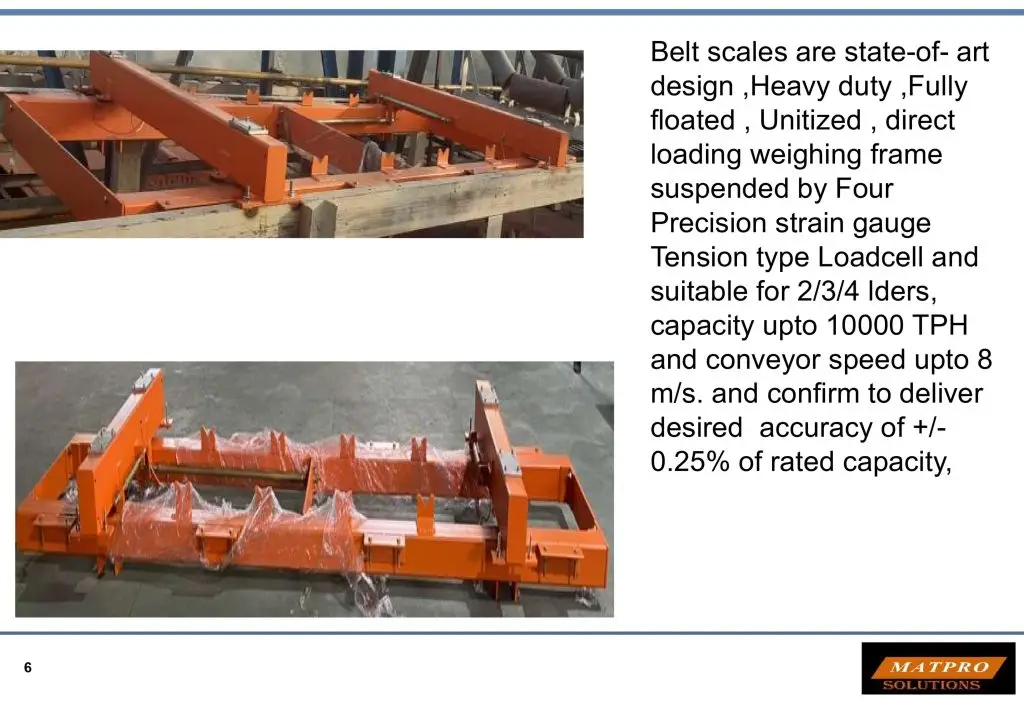

Conveyor Belt Weigh Scales

Application

- Process measurement & monitoring

- Inventory Monitoring & Control

- Material for blending Process

- Controlled Feed rate

- Batch loading

- Calculating basis of payment for custody transfer

Function

- To calculate flow rate two inputs are needed:

Belt Load – measured by the weigh frame of the belt scale system

Belt Speed- measured by the speed sensor of the belt scale system

BELT LOAD X BELT SPEED = FLOW RATE

By integrating instantaneous flow rate with time the Integrator also

calculates total material weight

Loadcell- Dynamic application

“S” Tension Type Loadcells

Environmental Protected Alloy Steel IP 67 Loadcell

Sensitivity 3 mv/V

Integral Cable 5 Mtrs

Excitation Voltage 10 -15 VDC

Non Linearity <0.025% of FS, Non Repeatability <0.01% of FS

Hysteresis <0.020% of FS

Operating Temperature -18 Deg C to +65 Deg C

Over Load 150% and Ultimate to 300% of FS

Weight Controller – MATPRO 7003

7” 800×480 TFT touch HMI panel.

24-bit ADC with internal resolution 1/1,000,000.

High sampling frequency 400Hz.

Definable DI/DO/AO

Loadcell Excitation Voltage/Current:DC10V/250mA.

3 Nos. Analog Output [AO]: 4~20Ma for Flow rate,Speed & Belt Load

9 Digital Input & 12 Digital Output ( optional ).

COM1: RS232&RS485.

Operating Temperature: -25~+45

Field Mounted Enclosure Environmental Protection Level of IP65.

Power required 230 VAC , Single Phase, 50 Hz

Tacho – Speed Sensor

High resolution –Tacho

Heavy Duty, suitable for outdoor

installation,

Aluminum–Die Cast enclosure

Digital, Self Pulse Generator

coupled type speed sensor with 50 ,

1000, 2500 PPR

Optionally – with Dual output

a) Belt scale controller

b) ZSS

Belt Scale

Installation

6 Point Piano wire alignment

Gravimetric Belt Weigh Feeder - Introduction

Gravimetric Belt Weigh Feeder is designed for precise accuracy on materials

with high flow rates and bulk densities in your most demanding applications.

Weigh Belt Feeder allows you to accurately control feed rates to your process

with a guaranteed accuracy of +/-0.5%. It can accommodate flow rates over 1000 TPH

Gravimetric Belt Weigh Feeder can be used in following industries

Gravimetric Belt Weigh Feeder – Four Essential Components

Cement

Steel

Power

Glass

Chemical

Tobacco

Coal Feeder - Retrofi

We undertake retrofitting of existing Coal Feeder by supplying compatible Loadcell , Tacho and Programmable Weight controller, without any modification at existing Control panel and Mechanical structure

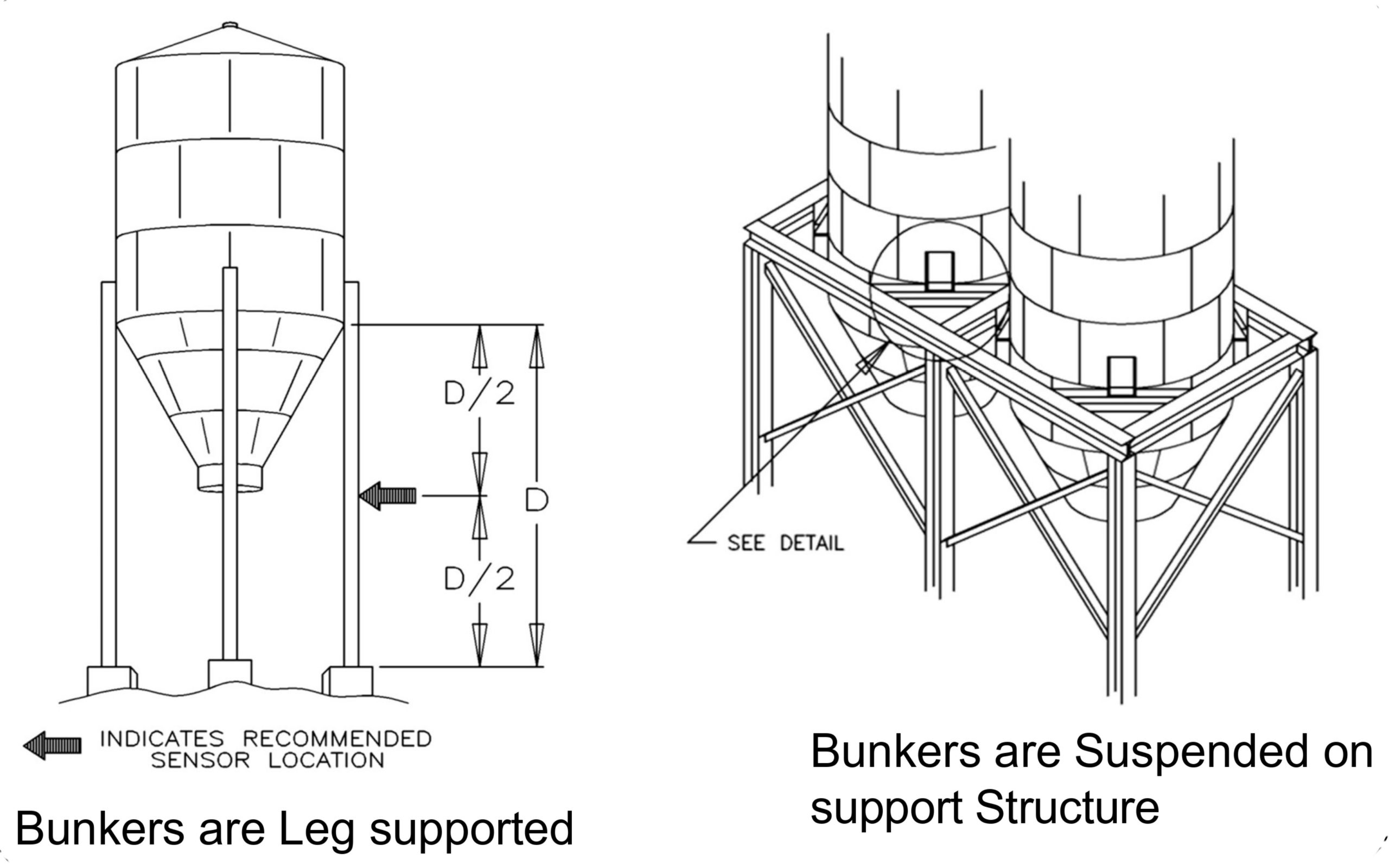

Bunker

Silo Level Measuring system

Bunkers / silos are always supported with multiple 4/ 6 / 8 points.

Nos. of support of Bunker/silo are always depends upon its capacity and its diameter

Current Conventional Technologies

•RADAR type level transmitter

•ULTRASONIC type level transmitter

Disadvantage of conventional Technology:

- Frequently failure of sensor due to dusty atmosphere of coal.

- Frequently calibration require

- In correct measurement due to different profile of material during feeding and discharging.

- Incorrect measurement due to difference in volume of material due to vary in % of moisture.

- Short term solution.

- A round strain sensor is press fit into the steel supports of Bunker/Silo

- Installing the strain sensor turns the support into a virtual load cell

- A insert type Strain Sensor based system infers level by measuring the weight of material inside a bunker/ silo.

- A insert type Strain Sensor measures weight by physically measuring the strain in the steel structural supports

- Substantially different and more accurate than measuring the distance to the top of the material

Two Stage Coal Sampling system

Bull Material Handling equipment