Bunker

Silo Level Measuring system

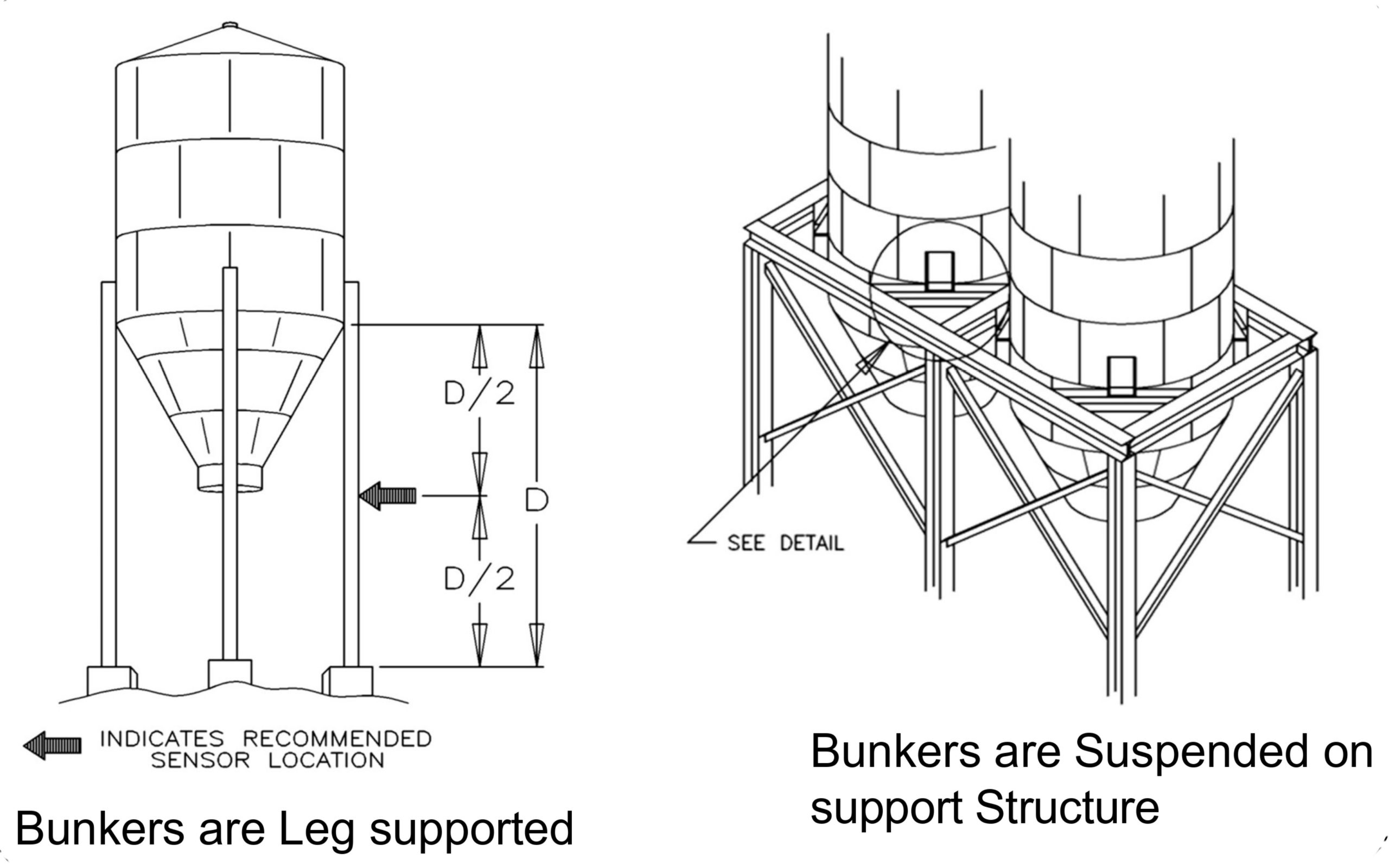

Bunkers / silos are always supported with multiple 4/ 6 / 8 points.

Nos. of support of Bunker/silo are always depends upon its capacity and its diameter

Current Conventional Technologies

•RADAR type level transmitter

•ULTRASONIC type level transmitter

Disadvantage of conventional Technology:

- Frequently failure of sensor due to dusty atmosphere of coal.

- Frequently calibration require

- In correct measurement due to different profile of material during feeding and discharging.

- Incorrect measurement due to difference in volume of material due to vary in % of moisture.

- Short term solution.

- A round strain sensor is press fit into the steel supports of Bunker/Silo

- Installing the strain sensor turns the support into a virtual load cell

- A insert type Strain Sensor based system infers level by measuring the weight of material inside a bunker/ silo.

- A insert type Strain Sensor measures weight by physically measuring the strain in the steel structural supports

- Substantially different and more accurate than measuring the distance to the top of the material